Picking, Packing & Despatch

RWM picking, packing and despatch functionality allows for the rapid conversion of orders to despatches. From robotics or via handheld scanners we can help drive warehouse operations regardless of specific site requirements.

Defeat slow picking processes

Accelerate processes, pinpoint inefficiencies, and uncover areas for optimisation like never before.

Pick & Pack accuracy

Reduction in team size with more efficient processes

Average cost reduction compared with incumbent

Visibility of all business-wide inventory

Mobile barcode scanning

Our innovative approach puts the full operational capabilities of RWM directly into the hands of warehousing staff through an intuitive and lightning-fast interface. By leveraging state-of-the-art handheld barcode scanning technology, our clients can streamline stock management and picking processes, achieving unparalleled speed and accuracy including real-time stock control. This ensures every order is flawlessly picked, packed and shipped, delivering exceptional efficiency and reliability.

RWM accommodates

Comprehensive picking, packing, and despatch features designed to optimise warehouse operations and maximise efficiency.

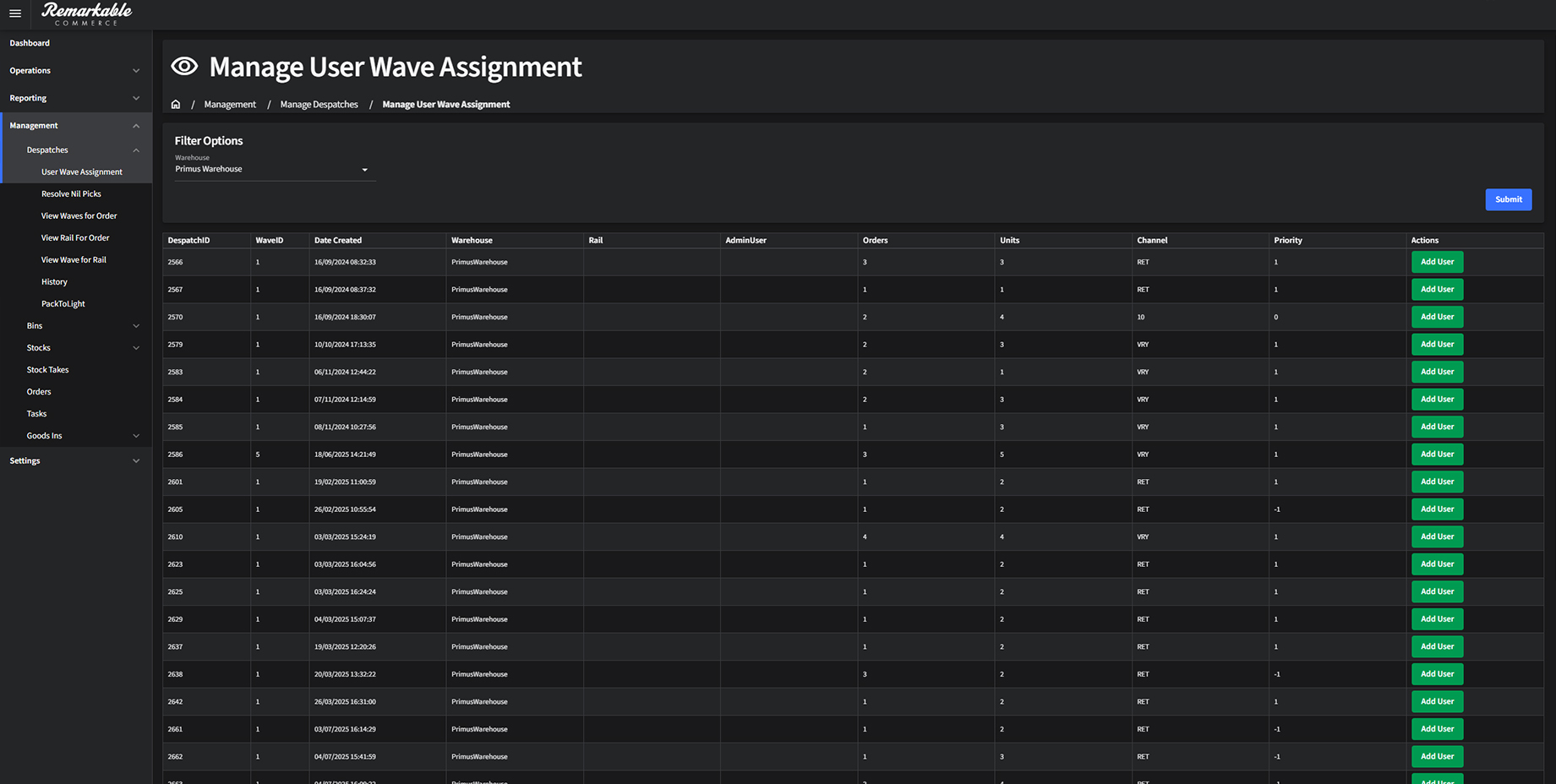

Dynamic splitting of waves

Large dispatches may be divided into single or multiple waves according to preferred picking size to facilitate the picking process.

Large Order received

Large order received from NEXT API for Sarah Johnson

Wave 1 allocation

Allocated to wave #2112

Wave 2 allocation

Allocated to wave #2113

"Remarkable launched the first WMS for Yours Clothing in 2009, today the platform has evolved to support all despatch, logistics and distribution processes including store replenishment. RWM manages over 20 multi-channel marketplaces, 6 brands, and 14 international trading websites."

RWM manages over 20 multi-channel marketplaces, 6 brands, and 14 international trading websites.

Estimated RWM will process over 5m orders for Yours Clothing in 2025.

Over 100,000 SKUs and more than 2 million units of stock individually tracked.

Intelligent snake picks to minimise footfall distances.

Android based HHT scanning technology, providing rock solid connectivity and rapid speed.

Supporting over 200 warehousing staff with advanced KPI metrics.

Support for multiple warehouses, multiple configurations such as mezzanines, zones, pallet locations, high bays.

Let's talk warehouse!

We work with brands handling 30 to over 30,000 orders per day - helping their warehouse operations teams to become more efficient, reliable and stable. Become Remarkable.